How to fix a Mechanical Seal on a Boiler Agitator

adminAt first glance, the mechanical seals on bigger boilers with agitators may seem ""over complicated"". Once you understand them, it however, makes perfect sense.

Lets start with an explanation on how the mechanical seal works.

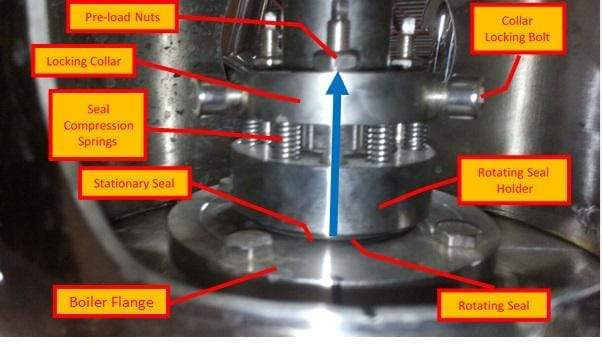

The seal consists of two main parts: A locking collar and a rotating seal holder. The shaft from the electric motor connects through the centre of these two main parts to the agitator inside the boiler.

Between the Rotating seal holder and the boiler flange are two seals. The top rotating seal is fitted at the bottom of the rotating seal holder and seals onto the Stationary seal that is fitted into the boiler flange. These two seals are pressed onto each other by the seal compression springs.

If the seal is leaking, the rotating seal is not pressed firmly against the stationary seal.

Figure 1

The locking collar is clamped on the agitator shaft and cannot move up or down. The pre-load nuts are tightened and are causing the rotating seal holder to move up (Blue arrow). This will effect the rotating seal to move away from the stationary seal and cause the seal to leak.

How do I fix a Leaking Agitator Motor Seal?

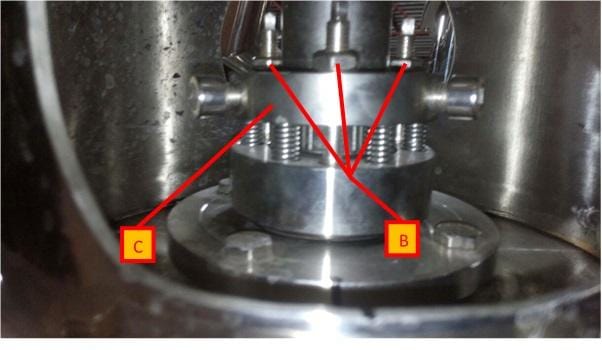

Step 1: Loosen the 3 bolts “A” (Figure 2)

Figure 2

STEP 2: Loosen the 3 nuts “B” on Pic 3 until they just touch the collar “C” (Figure 3)

STEP 3: Now tighten the 3 nuts “B” by three full turns to pre-load the springs (Figure 3)

Figure 3

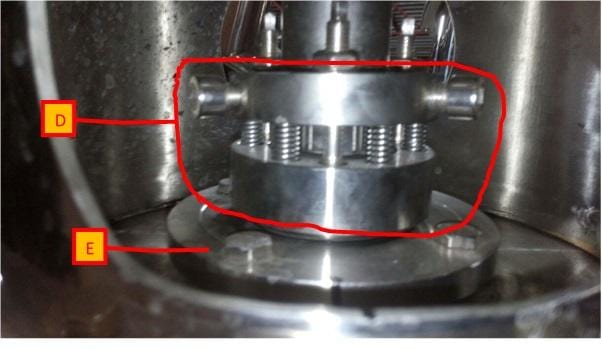

STEP 4: Push the whole seal assembly “D” down onto the boiler flange “E” as illustrated (Figure 4)

Figure 4

STEP 5: Tighten bolts “A” (Figure 2) to secure collar “C” (Figure 3) to the mixer shaft

STEP 6: Now loosen (or remove and store) the three nuts “B” (Figure 2)

The seal will now operate correctly.