How to bend copper pipe and tube to make your own condensers.

Gert BosmanOriginally posted in 2013 by Gert M Bosman

Bending copper coils is easy when working with (relatively) large coil diameters (in relation to the copper tube diameter). However, it becomes another story when you try to bend really tight coils.

When making distilling condensers it is important to get as much surface area of tubing into as little as possible space so as to improve the efficiency of the condenser as well as to save on costs. This requires the copper to be spiraled in as small as possible diameters.

This short article explain how to bend copper tubing into really tight coils.

The following abbreviations are used:

d = Diameter of copper tube

D = coil diameter into which the copper tube is to be rolled or spiraled.

Copper tubing (or pipe) is normally bought in two conditions:

- Soft annealed copper. These are always sold in rolls and this bends the easiest “straight from the coil”. This is the copper to use when making spiraled condensers.

- Cold drawn copper: These are always sold in straight lengths and is much harder than annealed copper because it work-hardened during the drawing process. It needs to be annealed (see later how to anneal copper) before bending otherwise it bends very difficult and tends to collapse or crack easily. Not recommended for spiraled condensers in distilling equipment.

For large coils: (D > 6 x d):

It is quite easy to bend copper tubing when the diameter around which the copper tube is to be bent is more than 6 times the diameter of the copper tubing.

Just roll the copper tubing around a pipe with suitable diameter by hand. It is easy and the coils will not collapse.

Medium tight coils (d x 5 < D < 6 x d):

For bending diameters between 5 and 6 times the diameter of the copper tube, commercial tube benders work quite well.

Bending tools or bending springs can be used successfully.

Unfortunately the bending tools are suitable only for 180 degree (or less) bends and cannot bend coils as the tool gets in the way of the copper tubing when making coils. They are also restricted to the diameter of the tool mandrel.

The springs works well but cannot bend into too tight coils. When trying to bend small diameters with them, the springs can get DIFFICULT to remove from the copper tube.

Tight coils (D < 5 x d):

However, when the bending diameter becomes less than 5 times the tube diameter, the copper tube tends to collapse/buckle quite easily. The more the copper is annealed (softened) the easier it collapses as well.

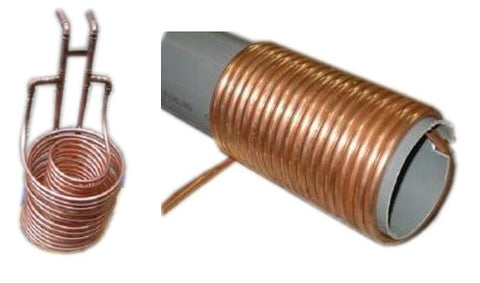

Examples of tight diameter rolled coils:

The following method is easy to use to bend really tight diameter coils and use the product called “Coppabend” from Distillique.

Coppabend is a non-lead material that melts at about 70—80 degree C and is ideal to fill (to prevent buckling/collapse) and bend copper tubes into really tight diameters as is sometimes used in distilling condensers / heat exchangers.

When using Coppabend it is quite possible to bend annealed copper into coils where D = 2 x d (i.e. the coil diameter is only 2 times the diameter of the copper tube itself!)

This makes for easy and neat tightly wound spirals and maximum condensation efficiency in distilling condensers.

How to work with Coppabend:

- Clean the copper tubing on the inside to eliminate dust and dirt. It can be rinsed with a good detergent..

- Plug the one end of the tubing (with something that can with stand heat of up to 100 degree C) or crimp the one end of the tubing.

- Heat and melt the Coppabend in a plastic jug that is suspended in hot (more than 70 degree C) water. (i.e. like in a bain marie)

- Hold the tubing at an angle (i.e. 30 degree from horizontal) and pour the melted Coppabend into the tubing. Do not pour the Coppabend vertically into the tube as air bubbles may then be trapped inside the tube.

- Now plug or crimp the open end of the tubing as well.

- Leave the tube to allow the Coppabend to set fully. This may take some time. (i.e. diameters of more than 12mm let it set overnight)

- Perform bending around a suitably diameter mandrel - slowly and smoothly.

- Unplug or uncrimp both ends of the bent copper tube and heat the tube with a hot air gun or hot water (hotter than 70 degree C) to melt the Coppabend.

- Drain the Coppabend into a suitable container for re-use.

- Rinse the empty tube with water to clean out any Coppabend residue. Coppabend is water soluble and will leave a clear finish.

- For large diameter copper piping (i.e. larger than 22mm) spiraled into very tight spirals, the Coppabend can be reinforced with fibre glass or Kevlar (but take care not to use more than 1 gram of Kevlar to a kilo of Coppabend).

Coppabend use:

Coppabend can be re-used over and over again.

Measure the inner diameter of the tube you would like to bend. This diameter is “d” (in mm)

Measure the length of the tubing to be spiralled: This is “L” (in mm)

Now calculate the volume “V” (in milliliter) of Coppabend to use:

V =3.15 x (d/2)^2 x L x 1000

i.e. for a tube with inside diameter 5mm and 1 meter long, you will use less than 20ml of Coppabend.

1 ml of Coppabend equals 1 gram.

Or, in other words: With 100g of Coppabend, you can bend more than 5 meter of 5mm ID copper tube in one go.

..and the Coppabend can be re-used over and over again!

How to anneal copper to make it easier to bend:

Heat the copper with a flame until it starts glowing red. Remember that when you heat copper, it will first go blue/black and then red. Once red, let it cool in air or quench it in water. The faster it cools down, the softer the copper will become. Easy as that!

Take note that copper hardens as soon as it is formed or worked on. Even very soft copper with work-harden very quickly and care should be taken not to bend copper in the same place more than once or twice.