Raw Materials for Fermentation and Distillation: Focus on Fruits

Annelize SteensmaLast month, we delved into the world of molasses as a key raw material for fermentation and distillation. This month, we turn our attention to the rich and varied world of fruits. Fruits have long been cherished for their ability to produce a wide range of alcoholic beverages, such as wine, ciders, brandies, mampoer etc. This article explores the role of fruits in fermentation and distillation, highlighting grapes and other common fruits used in these processes.

Grapes: The Quintessential Fermentation Fruit

Grapes, particularly those of the species Vitis vinifera, are the most preferred fruit used in alcoholic fermentation. The high sugar content of V. vinifera varieties at maturity compared to other types of fruit is a major factor in their widespread use in wine production. Wines made from grapes have a typical alcohol content of 10% ABV which is higher compared to most other fruits such as apples and pears that produce wines with an alcohol content of between 5 and 7% ABV.

Even though grapes are the preferred fruit based on sugar content, many other types of fruits are used to produce spirits such as Eau de Vie, Mampoer or Schnapps due to their interesting aromas and taste.

Brandy and Witblits: A proud South- African Spirit

Grapes play an important role in the South-African spirit world as grapes are the required raw material for brandy and witblits production in South-Africa. The only difference between the two products is the process of barrel-aging. Witblits is bottled as a white spirit whereas brandy has strict requirements with regards to barrel ageing.

Below are the four main types of Brandy in South-Africa and their laws:

Pot Still Brandy

- Distilled from fermented Grape Juice under excise supervision, below 75% ABV (this means that the alcohol strength of your distillate may not exceed 75% during distillation)

- Distilled using a pot still (a batch operated still)

- Matured 3 to 8 years in oak barrels smaller than 340lt

- If matured longer than 8 years, it must be done in barrels smaller than 1000lt (in other words, if you are ageing your brandy for more than 8 years, you are allowed to use barrels bigger than 340L, but smaller than 1000L).

- Alcohol content of 38% ABV minimum (the bottling strength of your spirits are allowed to be less than the typical 43% that is the legal limit of most spirits in South-Africa).

Brandy

(usually a blend between the above-mentioned brandy and white spirits made from grapes)

- Minimum 30% Pot Still Brandy (made by the process as mentioned above)

- Maximum 70% Wine Spirit (an un-aged brandy)

- Distilled off wine at minimum 60% ABV (this means that the alcohol content of your distillate is not allowed to be less that 60% ABV)

- Distilled off the leftover grape solids after grapes have been pressed during wine production

- The strength of the distillate may not be less than 95% ABV, or a mixture of both

- Alcohol content of 43% ABV minimum

Vintage Brandy

- Between 30% and 80% Pot Still Brandy, aged for a minimum of 8 years.

- Between 20% and 70% Wine Spirit, aged for a minimum of 8 years in Oak Barrels smaller than 340lt

- If aged longer than 8 years, the mixture or component must do so in barrels smaller than 1000lt.

- Alcohol content of 38% ABV minimum (again, the bottling strength is allowed to be less than the typical 43% ABV)

Estate Brandy

- Distilled from fermented grape juice under excise supervision, below 75% ABV (the strength of your distillate is not allowed to exceed 75% ABV)

- Matured 3 to 8 years in Oak Barrels smaller than 340lt.

- If matured longer than 8 years, it must be done in barrels smaller than 1000lt.

- Alcohol content of 38% ABV minimum

- Wine used for distillation must have been made on the farm or estate, exclusively from Grapes farmed on the farm or estate.

- Distillation process must have been performed on the farm or estate.

- Aging process must have been performed on the farm or estate.

- Bottling process must have been performed on the farm or estate.

Other Fruits in Fermentation:

While grapes dominate the world of wine, many other fruits are used to produce a variety of alcoholic beverages. Fruits such as apples, plums, peaches, pears, berries, and tropical fruits like mangoes, pineapples, and bananas can all be fermented to create unique wines and spirits. Spirits made from fruit other than grapes are usually referred to as mampoer in South-Africa, Eua-de-Vie in France, and Schappes in Germany. These are usually unaged fruit-based spirits meaning that they have no oak contact in order to preserve and accentuate the fruity aromas.

Fruits other than grapes usually have a low sugar content

The Table below show the sugar content in % by weight of various fruit.

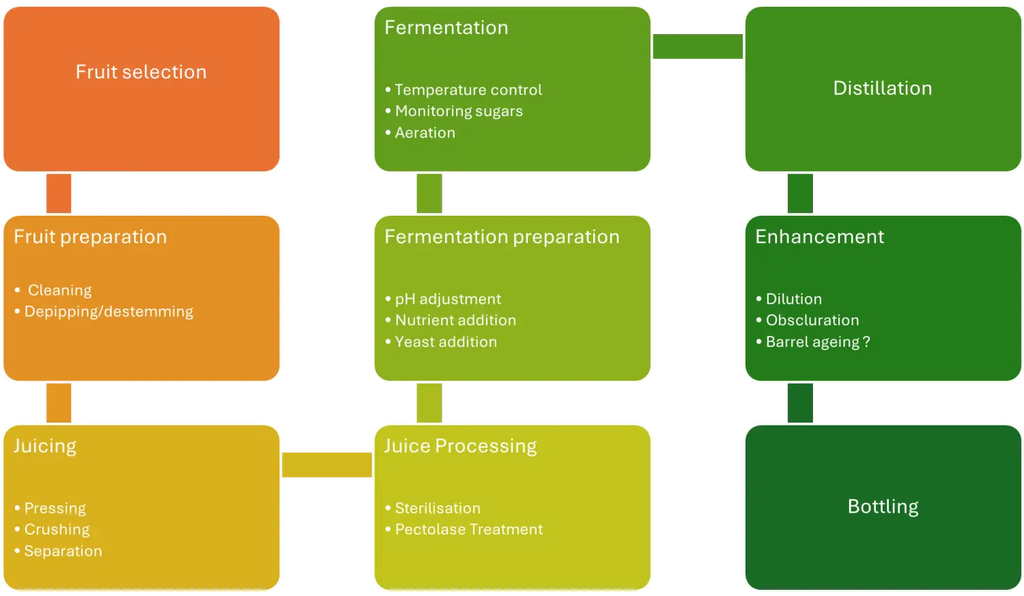

Spirit production process using fruit:

Below is a diagram showing the typical process of making spirits using fruit.

Preparing Fruit Must and Juicing:

Different fruits require specific processing techniques due to their physical differences. For instance, grapes can be pressed to extract juice directly, while fruits like plums and peaches need their stones removed and then shredded to release the juice. If you're making fruit fermentations, research the processing methods required for each specific fruit before starting.

Juice processing and fermentation preparation:

Once the juice is extracted, certain chemicals such as pectinases and sulphur additions are made to clarify the juice and to kill of any spoilage organisms that might be present. It is important to check the pH and ensure that it always remains between 3,5 and 4 during fermentation. A too high pH will put your fermentation at risk of contaminating organisms, and a too low pH will kill your yeast and you will end up with a stuck fermentation. pH adjustments can be made with a fruit based acid and potassium carbonate.

Yeast is added to the prepared juice to start the fermentation. The fermentation temperature is usually kept at 20-25°C. During fermentation, the sugar content is regularly monitored which serves as an indication when the fermentation is complete. After fermentation, the wine undergoes siphoning or racking to remove sediments, followed by distillation.

Distillation:

Pot stills or ay other low reflux stills are usually the preferred type of still to produce fruit-based spirits. Low reflux stills usually retain the flavours of the fruit allowing the natural flavours to be present in the final spirit.

Below is an alembic potstill which is typically used to produce fruit based spirits.

Maceration Method for Fruit Spirits:

Fruits are not necessarily used to make fermentations, they are sometimes used as a natural flavourant in neutral spirits to produce liqueurs. This process involves soaking fruits, berries, or even nuts in neutral alcohol to extract their aromas, flavour and natural sugars. You can learn more about infusing spirits in our W4 Online Course.

Conclusion:

Fruits provide a versatile and flavourful raw material for fermentation and distillation, offering a broad spectrum of alcoholic beverages. From the traditional grape wines and brandies to exotic tropical fruit wines, the diversity of fruits allows for endless possibilities in crafting unique and delightful drinks. Whether using high-sugar grapes or enhancing other fruits with added sugars, the art of fermentation and distillation transforms these natural resources into cherished alcoholic beverages.

For more detailed information on fruit-based alcoholic beverage production, including specific recipes and techniques, visit the Articles section on the Distillique website. Stay tuned for more insights and guides on mastering the craft of distillation!