Choosing Suitable Fermentation Vessels

adminAs with many thing in the Home and Craft Distilling Arena's, people make choices regarding their fermentation vessels based on training, education, experience, advice, habit, tradition and budget. As a result, many different containers and vessels are used - especially at the Home Distilling Level, for fermentations.

Just some of these vessels are:

- Food grade buckets (25 litre capacity)

- Glass carboys

- Food grade polyethylene or poly-propylene plastic storage bins

- Epoxy-coated Fibreglass containers

- Glass aquariums (manufactured with “aquarium grade” silicone sealant)

- Wooden barrels

- Specially designed Stainless-steel fermentation tanks – IDEAL especially when jacketed

- Stainless steel beer kegs

- 1 000lt PPT Flow Bins (not ideal due to square shape causing “dead zones”

- Wooden “Washbacks” or barrels

When making a decision about what you intend to use for your fermentations, the following factors should be kept in mind:

No Leaching of Flavours, Aroma's or Chemicals into the Fermentation

The ideal fermenting container should first of all, not impart or leach any flavours, chemicals or odours into the fermentation, or absorb any colour, chemicals or odours from a fermentation. This is true for all fermenting vessels other than wooden barrels where the developing flavour is deliberately enhanced.

“No leaching” is perhaps the most important requirement when looking at suitable containers. “No leaching” characteristics are normally defined by the descriptive “Food Safe”. Normal plastic buckets or bins are unsuitable unless made of food grade plastics that are not affected by alcohol.

Also note that there is a marked difference between alcohol resistant and alcohol tolerant, in terms of the strength of alcohol it can handle, and the period of time it can be stored.

Containers must be Sealable and Airtight

Your fermenting vessel should preferably be sealable and airtight, but with a way for CO2 to escape. It is unfeasible to make large commercial fermentations vessels air tight, so at that scale we only strive to prevent airflow totally removing the CO2 layer on top of the fermentation. This is accomplished by keeping sufficient headspace at the top of the fermentation vessel (10 to 15% of volume) and ideally keeping the access limited to a manhole or a similar access point.

During fermentation, the very first phase (few hours to two days) of fermentation requires oxygen, thereafter no oxygen should be allowed to enter the fermentation vessel.

The oxygen required during the first phase is provided through the process of aeration.

The first phase can be accommodated in open tanks, whereas during the second stage, the mash should be contained in an airtight or limited airflow container.

Should airtight containers be used for fermentation, as is recommended with smaller fermentations which are more susceptible to airflow interference and CO2 Cap disturbance, we should allow for the CO2 gasses that develops during fermentation, to escape readily without building pressure within the container.

Failure to do so will lead to an increased level of Carbon Dioxide within the solution, which will negatively affect the fermentation, an in extreme cases (depending on the vessel used) the pressure build-up can damage or explode the fermentation vessel.

Some food grade plastics, especially when thin, do allow slow oxygen entry into the mash and should only be used for fast fermentations.

Fermentation Vessels should be Robust and Manageable

The fermenting vessel should be easy to handle, scratch resistant, not break easily, be opened and cleaned with ease and generally be of robust design. This is why Stainless-Steel fermentation vessels are the ideal. Many distillers do start with Food Grade PPT Plastic Fermentation Vessels however (to save on the start-up cost). It is important to remember that although there is nothing wrong with this (except maybe aesthetics) these plastic fermentation vessels have a lifespan of approximately 3 years, before the continuous exposure to ethanol starts to weaken the plastic and make it go brittle. At this point they need to be replaced.

Fermentation Vessels should have a suitable Geometry and Design

Suitable containers will also have a geometry that allows for the natural circulation of the fermentation as CO2 escapes from the mash without creating “dead spots” anywhere in the container. A cylindrical vessel with height approximately 2 times its diameter is ideal for this purpose.

Square or very flat containers require some means to stir the mash during fermentation. If a mechanical means is employed, be careful that the mechanical stirrer does not scratch the fermenting vessel.

Also consider taking of samples and draining of sediment. Tanks with a pronounced or even slight taper at the bottom (conical tank) makes the removal of sediment a lot easier, as do drain valves located above the bottom of the tank, allowing tank drainage without draining off sediment.

Sample taps are also very important for the monitoring of the fermentation. It is not recommended to try and take a sample out from the main drain valve, as you will make a mess and waste fermentation. A smaller sample tap located higher up on the tank is recommended.

In addition, your tank should provide you with a means to measure the volume of the liquid inside. The ideal would be a calibrated level indicator tube running along the side (normally glass) but there are also other options – digital level indicators, or a normal “dips-stick” you can make yourself.

Volume measurement is very important for record keeping and auditing reasons, especially when inspected by Excise Tax and SARS inspectors.

Fermentation Vessel Size

To lower your CapEx (Capital Expenditure) when setting up your distillery, and to allow a better use of you time during the week, it is recommended to use Fermentation Vessels double the size of your boiler capacity. This allows you to then do two distillation runs over two days out of one fermentation tank.

Alternatively, when doing stripping runs, you can do two stripping runs a day out of one fermentation.

It should be avoided to use odd size fermentation tanks for practical reasons – i.e. if you have a 200lt boiler, you should have a 400lt fermentation tank, not 480lt or 520lt, as this will leave you with leftovers or force you to fill the boiler only partly. For commercial purposes – select the size to equal, double or triple the capacity of your biggest still.

Also note that there is a difference between Fermentation Tank Capacity and usable capacity. Remember that you cannot fill the fermentation vessel completely. You only fill it to about 80% of its capacity to allow for the fermenting cap to develop on top of the mash. The fermentation cap can easily reach a thickness of 15% of the tank height – depending on your mash or wort type.

A 440lt Fermentation Tanks therefore only has a 400lt usable capacity.

This same rule will also apply to boilers, so if the rule of multiplication is followed (i.e. 200lt boiler, 400lt tank / 400lt boiler, 800lt tank) the liquid amounts will always be in line as the headspace requirements in both boilers and tanks would be the same as well.

NOTE: There is a point where a fermentation tanks’ size can negatively impact the fermentation, but this should never happen on craft level, and there are ways around it.

Pressure inside a Fermentation Vessel affects the activities of the Yeast. As a rule of thumb:

- 0.2 atmospheres pressure Stimulates yeast growth.

- 0.5 atmospheres pressure Begins to exert a negative effect on yeast growth.

- 3.0 atmospheres pressure Stops growth

BUT 3.0 atmospheres pressure does NOT stop fermentation-alcohol production.

Now when we talk about pressure inside a Fermentation Vessel, most people would immediately think about, or assume we are talking about CO2 buildup. What we need to keep in mind is that the weight of a column of liquid also increases pressure - much like we experience when diving into the ocean - the deeper we go, the higher the pressure.

A 3-meter-high fermenter has a pressure at the bottom of the tank of 0.3 atmospheres, therefore the higher the tank, the greater the pressure, and the greater the impact on the fermentation. By that calculation however, only at about 5 meters will we reach 0.5 atmosphere pressure, so any normal size tank should have no impact on the fermentation.

If you are concerned about this, mechanically agitating the fermentation by pumping it from the bottom to the top (ideally without splashing) will keep the fermentation circulating.

Airlocks, Bubblers or Pressure Release Valves

Adding an air-lock bubbler to a fermentation bucket, is a great way of keeping oxygen, bacteria and fungi out during fermentation and allows the carbon dioxide to safely escape. It further provides a visual and audible confirmation that fermentation is in progress. You will hear a soft reassuring "blub-blub-blub" often, telling you the fermentation is doing just fine.

Some distillers find air-bubblers a nuisance. Each time you open and close the lid, the water in the air bubbler might spill and has to be re-filled. If you don't use an air-lock bubbler, drill a small (i.e. 3mm) hole in the lid to prevent pressure build-up during fermentation. Provided you left enough headspace in the fermentation vessel, you should not have any problems.

Air-Lock Bubblers are also limited in terms of the maximum fermentation vessel size it can be used with. Any fermentation vessel larger than 50lt will tend to create too much Carbon Dioxide and Pressure for a Bubbler to handle. On these fermentation vessels, we recommend using one-way valves instead of bubblers as they are more effective.

The drawback of using a one-way valve is of course that you cannot see the fermentation “bubbling” away.

This is not necessarily a bad thing, as people tend to use the speed of the “bubbling” and its presence as indicators of Fermentation Speed, Effectiveness and Continuity, instead of relying on the SG Measurements as they should.

If for some reason, you do want to check the “bubbling” on a larger fermentation vessel using on-way valves, it is quite easy to connect a hose to a one-way valve and drop it in a bucket of water.

Another version of a one-way valve that can be used on a fermentation vessel is on Odour Trap. These one-way valves contain Activated Carbon which acts as a filter, trapping odours and smells that some might consider offensive or unwanted.

Should we reach a future point in South African where legislation changes allowing Craft Distilleries to open up in Commercial areas, Odour Trap Air Locks will start playing a very important role in proving that this is not necessarily a noxious industry.

Temperature Control in Fermentations - Heaters and Heating

If you are a Home Distiller, or busy with product development, it might be necessary to provide a heat source for your fermentations during winter to ensure optimum temperature (especially if your fermentation buckets is left in your garage for instance).

When fermentation temperatures are below 20 °, it slows down and takes longer to ferment. At temperatures below 15 °, some yeasts would even stop fermenting and leave you with a "stuck" fermentation (Wine and Beer yeasts do not have this problem). Small fermentations (100lt and below) are quite susceptible to ambient temperature fluctuations and need some additional help.

A normal aquarium heater with thermostat control is ideal to regulate fermentation temperature. Select one with 50 or 75W output for small (up to 200L) and 250 or 300W for large (up to 1000L) fermentations. The aquarium heater should have an adjustable thermostat. Your local pet shop should have quite a range to select from.

The heater is used to maintain a constant heat range between 20 and 28 ° Centigrade, and can be placed inside the fermentation vessel (20lt and larger) or in water surrounding the fermentation vessel (smaller than 20lt).

Another benefit from using these types of heaters inside a fermentation vessel is that it creates a limited convection effect (movement of the particulates within the fermentation) allowing the yeast, sugar and nutrients to interact more effectively.

When fermentation temperatures are below 20 °, it slows down and takes longer to ferment. At temperatures below 15 °, some yeasts would even stop fermenting and leave you with a "stuck" fermentation.

With larger fermentations, especially those in fermentation vessels that provide a bit more protection against ambient temperature fluctuations, the heating of fermentations is not as important as cooling.

This fermentation cooling is normally accomplished through jacketed fermentation tanks or cooling coils, but these same methods can also be used to heat a fermentation by pumping warm water through the jacket and cooling coil instead of cold.

Temperature Control in Fermentations - Cooling Jackets, Coils and Cooling

If you live in a really hot environment, and you are using small fermentations (home distiller or product development), it might happen that the temperature of the fermentation goes beyond 30 °.

Excessive heat in a fermentation can cause the fermentation to progress too fast (forming more unwanted congeners – bad flavours and aromas) or the yeast might denature and die if the fermentation gets too hot. If this is the case, it might be necessary to provide some cooling for the mash or wort to ensure good fermentation.

On small fermentations, this is not really a problem (i.e. up to 50 litres), as the fermentations are easy to cool, either by placing them in a cold-water bath, moving them to cooler room or area, running cold water over the fermentation vessel, etc.

With large fermentations (i.e. 500 litres) this becomes a real problem as the fermentation creates its own heat.

Fermentation is an exo-thermic reaction, meaning heat energy is released during the fermentation process. It is this heat energy that allows the yeast cells to survive during the fermentation process in the absence of oxygen.

The reason that this becomes a problem however, is that heat energy translates to kinetic energy inside a solution, therefore the more heat energy is released, the more movement takes place, and the more movement takes place, the more fermentation takes place.

This reaction builds exponentially, what we refer to as a run-away fermentation, unless the temperature of the fermentation is controlled through cooling.

The most effective way to accomplish this is in a stainless steel jacketed fermentation tank, where cooling water can be circulated through the jacket and thereby control the temperature of the tank and the fermentation.

In plastic fermentation tanks this is more difficult, but it can still be accomplished by inserting a cooling coil inside the tank.

This cooling process can of course be automated.

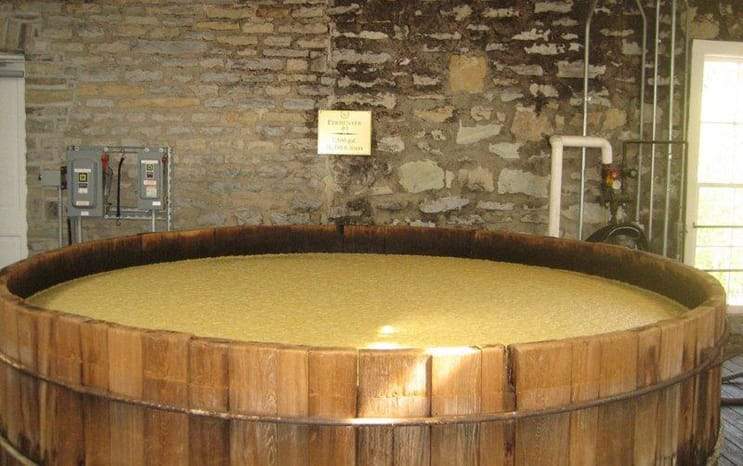

Using Wooden “Washbacks” instead of Stainless-Steel Fermentation Tanks

If you were to visit a large selection of distilleries from all over the world, you would see that some distilleries have these traditional and often very old wooden washbacks (mostly found in the Whisky world), which they claim contribute to the flavour of the spirit. However, many others (if not most) use stainless steel. And some a mixture of both.

If wooden washbacks make a difference to the product, why would distillers use anything else?

Like many things in the spirit world, to get to the truth of the matter we need to revert to science, as the answer does tend to differ from distillery to distillery, more often than not, influenced by marketing and tradition rather than the facts.

Now, Washbacks are tall, circular vessels used by both the brewing and distilling industries to ferment wort into beer. They vary in size and shape, but their most important feature is their size – washbacks must be large enough to hold (in some cases) thousands of litres of wort with extra space above the liquid for the mixture to foam up as the yeast expels carbon dioxide.

Some have switchers (rotating blades) at the top to prevent vigorous washes from bubbling over; most have carbon dioxide extractors (although only one Scottish distillery, North British, collects its carbon dioxide to sell to the carbonated drinks industry – the rest is vented to the atmosphere) and all have lids to prevent contamination from foreign objects. The most modern designs also have a sloped base to aid drainage and cleaning.

Washbacks can be made from any sturdy material that is easy to clean and repair, but are traditionally made from timber, usually pine or larch for their long, straight form and tight structure that’s impervious to leaks. There was one instance of concrete washbacks being installed by Joseph Hobbs at Ben Nevis distillery in the 1950s, but these were subsequently removed in 1981 by Whitbread. Concrete Fermentation Tanks are still quite common in the Wine Industry though.

By the start of the 20th century, stainless steel had become renowned as a durable and easy-to-clean metal with a multitude of uses. After the Second World War, when it became more affordable, stainless steel washbacks were introduced to the Scotch distilling industry, but the first recorded instance of their installation is debatable.

In 1949, William Delme-Evans incorporated stainless steel washbacks into Tullibardine, while George Christie installed them at Speyside distillery in 1955, although it failed to open until 1990. Indeed, almost all new distilleries built between 1960 and 1980 installed Corton or stainless steel washbacks, the only two exceptions being Clynelish (larch, 1967) and Mannochmore (larch, 1971). Both were built by Scottish Malt Distillers (DCL), which incidentally never installed stainless steel in any of its plants; nor has its successor, Diageo, replaced any of its wooden vessels.

Now, why was stainless steel so popular and why did DCL – and, even later, Diageo – refuse to install it or even ‘upgrade’ its distillery washbacks?

The decision mostly comes down to cleanliness, alcohol yield and consistency.

Yeast is a fussy fungus and demands the perfect set of conditions in order to convert all the wort’s sugar into alcohol and carbon dioxide. Some of these conditions – nutrients, pH and oxygen – are already contained within the wort, but there a few which are controlled by the washback.

Yeast thrives in steady, warm temperatures – 25-35°C is the optimum – but, as it grows, it emits heat. The washback therefore needs to be made of a heat-resistant material that can maintain the wash temperature evenly. As wood does not conduct heat it makes the perfect insulator, though if the wash temperature rises too high, it can be difficult to reduce.

Adjusting the wash ‘setting temperature’ depending on ambient conditions in summer or winter is the most common way of ensuring the temperature of the wash doesn’t rise too high. While there is little need for adjusting temperature once fermentation is under way, the exterior of stainless steel washbacks can be sprayed with cool water, be jacketed, or have cooling coils installed in the sides of the tank.

This cannot be accomplished with wooden washbacks (although a cooling coil could be placed inside the wort).

However, the most common reason for a failed fermentation is cleanliness, or lack thereof, which can lead to infection of the wort, particularly by a bacterium known as lactobacillus.

Lactobacillus competes with the yeast for sugar in the wort, raising its acidity and preventing the yeast from doing its job properly, ie making alcohol. Wort can be infected by lactobacillus and other off-flavour-producing bacteria very quickly, meaning strict control over the cleanliness of the washback is imperative.

Wooden washbacks are porous and full of nooks and crannies, such as between planks and in the corners of the base, where harmful bacteria can accumulate and spoil the wash. Usually a jet-powered spray of hot water and detergent, followed by around 30 minutes of steaming, can kill most micro-organisms, though some can linger. The smooth surfaces of stainless steel – particularly those with conical bases – can be more reliably cleaned, ensuring all the unwanted bacteria are killed off.

Unlike cask maturation of whisky, the timber itself does not affect the flavour of the wash – the short time it’s resident in the washback, its low abv and the age and type of the wood (up to 100 years, not oak) sees to that. Rather, the effect on flavour that you’ve heard so much about with wooden washbacks originates from claims that micro-organisms that survive cleaning regimes contribute flavour congeners to the wash.

Some distillers have noted that a switch over to stainless steel has resulted in a noticeable change in the spirit’s organoleptic properties. This is the core reason why Diageo has not replaced any of its wooden washbacks with stainless steel.

Others, such as Glenfarclas, which gradually swapped its wooden washbacks for stainless steel during the 1960s, believe it makes no difference at all – even so, Glenfarclas chairman George S Grant ensured the process was conducted slowly to monitor changes in the spirit. Note that, in both instances, maintaining product consistency is of utmost priority.

In fact, Glenfarclas retained its wooden lids in a nod to its heritage and the traditional washbacks it had housed since the 1790s. For many distillers, the decision to retain or even install wooden washbacks in new plants, especially in new Craft Distilleries, comes down to their romantic appeal, and has nothing to do with cleanliness or consistency at all.