Can an Alembic head be upside down...and if so, why is it wrong??

Gert BosmanDistillique often gets questioned on the way we orientate our alembic heads on our boilers. It seems that a bit of confusion was created by advertisers/equipment sellers that positions alembic heads upside down.

Have a look at the following image of an upside-down alembic head on a boiler as part of a distilling setup.

If you are not familiar with the purpose of reflux during distilling, you would not notice that the copper alembic head is actually upside-down on the boiler!

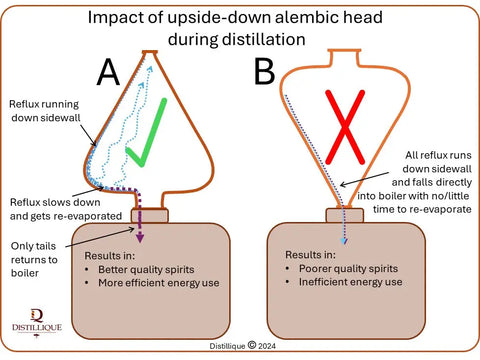

The above diagram, shows how a conical alembic head should be orientated on a boiler during distillation (A). The alembic head has a large surface area which allows some of the vapor/steam coming from the boiler, to condense against the cooler wall of the alembic head. This condensation, that does not follow the main vapor path, is called reflux.

On alembic head (A), the reflux runs down the sidewalls until it reaches the horisontal (or almost horisontal) sides of the alembic head. Here the reflux slows down a lot and the heat coming form the hot boiler vapor, has time to re-evaporate part of the reflux. This causes the more volatile components (i.e. the hearts of the spirit), to evaporate more than the less volatile fractions of the reflux.

Only the least volatile fractions (i.e. fusel oils) are therefor returned to the boiler. This results in a "cleaner" distillate. We also assume that the heads has already been extracted and discarded before this hearts run.

On alembic head B, the reflux runs down the sides of the alembic head and straight back into the boiler because the heat from the hotter vapor from the boiler, does not have time to evaporate part of the reflux.

Because no reflux gets re-evaporated (or very very little), there cannot be another separation of the fractions in the reflux.

In other words, the energy that we used to produce vapors that condensed against the alembic head, was lost with no enrichment of the reflux and therefor wasted energy.

Reflux consists of two main fractions: the more volatile fractions and the less volatile fractions. The purpose of reflux is to get a re-evaporation of the reflux to ensure enrichment of the vapor in the more volatile fractions. Only the less volatile fractions of your mash should be returned to the boiler.

Conclusion : With the alembic head turned upside-down on a boiler, both the distillate quality and energy efficiency of the still suffers.

Make sure your still's alembic head is orientated the correct way to improve both the quality of your spiirts and the energy efficiency of your still.