Bottles and Bottling - What do I need to keep in mind?

adminFinding the right way to bottle your product is as important as finding the right way to make your product. Many Craft Distillers make some avoidable mistakes in their initial setup, that can lead to them having to change their packaging, capping their growth potential, or spending a lot more on bottling and packaging than they should.

A couple of factors need to be kept in mind when deciding on your bottling line:

- Bottle Design

- Bottle Filling

- Closure

- Labelling

What should I keep in mind regarding Bottle Design?

Keep the following in mind when choosing your bottle.

Bottle Size

Nowhere in the Liquor Act or the Liquor Products act are any references as to bottle volume specifications for spirits.

This might lead to the perception that there are no legal requirements and that we may have spirits in any bottle sizes we want to.

There is however a big catch in all this.

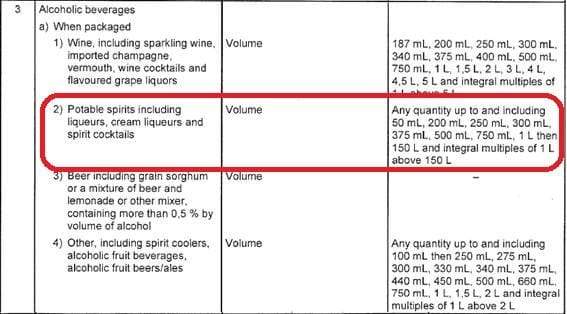

Although the liquor related acts does not prescribe any volumes, there is a South African National Standard (SANS 289) that actually prescribes Labelling Requirements for Prepackaged Products and General Requirements for the Sale of Goods, subject to legal Metrology Control.

From this National Standard the following extract shows clearly the legal bottle sizes in which you may sell spirits:

Within these confines, the following still applies:

Avoid non-industry standard bottle sizes. Industry standard is 750ml, and all hospitality point-of-sale systems work on this standard. Hospitality outlets could be hesitant to stock a product for which they would need to change their processes and systems.

Target market also impacts on bottle size. Tourists prefer smaller bottles – 250ml, 375ml and 500ml – as this allows them to buy more bottles while still staying under the allowed limit they may carry on a plane, for gifting, consumption or souvenirs.

The industry has been taking advantage of duty-free shops for a long time to sell larger bottles (1 000ml) at a lower price (due to excise tax not being applicable). In practice this no longer really works, as shop rentals are so expensive in Duty Free areas that the products are priced the same or even higher, but Duty Free still sometimes requests larger bottles.

Export producers should consider the industry standard in the country to which they are exporting, as this sometimes differs, and when exporting your product needs to comply to the regulations of the country you are exporting too. This is one of the reasons for the increase in 500 ml bottles currently on our shelves, as it is a bottle size shared by most countries, and this allows us as manufacturers to use the same bottle size both locally and in the export market, which makes our logistics chain easier to manage.

Bottle Shape

If you look at the bottle shapes pictured on the next page – although they are very attractive bottles, stockists (especially liquor stores) might be hesitant to stock them due to the excessive shelf space they take up – being too wide either at the base or the top or as a whole.

As a producer, you need to keep in mind the requirements of your clients and stockists and realize that shelf space is at a premium – this is why big brands pay for preferred shelf space or a certain amount of shelf space. As Craft Distillers, we cannot afford to follow this practice, so we need to ensure our product appeal to the stockist and his operations.

Bottle shape will also impact your labelling process. We get round bottle labellers and flat bottle labellers, but anything in-between needs to be either purpose built (which is prohibitively expensive) or applied by hand (which limits your production capacity). You should therefore consider all aspects of the process before making a decision.

Keep in mind that bottle colour also plays a role. Clear glass bottles are probably the most common, and in some cases, i.e. a coloured Gin, clear glass is important in order to properly show the product. Brown glass bottles are however recommended for any product where the aroma and flavour molecules are very important, delicate, and susceptible to Ultra Violet light. UV light will over time destroy these delicate molecules, leading to changes in flavour profile, and eventually a total lack of flavour and aroma. Using a brown glass bottle eliminates this possibility.

What should I keep in mind regarding Bottle Filling?

As a rule, most of our clients use 4 head semi-automated bottle fillers. There are several reasons for this.

- Firstly, it is the most cost-effective option in terms of scale, capacity and price.

- Secondly, at a bottle filling rate of 450 bottles per hour it allows you to grow your distillery from a small operation to a large one without recapitalising on bottle filling equipment.

- Thirdly, it has an automatic reservoir filling system with a built-in pump that cuts out the need for additional equipment or manual reservoir replenishment (but as the actual filling system is gravity fed, you can still use the bottle filler in a power outage by just manually topping up the reservoir - important to consider with loadshedding).

PLEASE NOTE – THE FOUR HEAD BOTTLE FILLER PICTURED IS NOT SUITABLE FOR HIGHLY VISCOUS LIQUIDS (I.E. A HIGH-DENSITY CREAM LIQUER) OR FOR LIQUIDS CONTAINING SOLIDS OR PULP (I.E. LEMONCELLO OR GRANDILLA PULP LIQUER)

When working with high density or highly viscous liquids we recommend a vacuum type filler unit. Pictured below is a single head filler of this type, as well as a multi head filler.

Vacuum fillers are normally Volumetric, while Gravity fillers are more popular because they are Level Fillers. This becomes quite important if you are dealing with bottles that have slight imperfections or inconsistencies. Using a Volumetric Filler on these bottles would mean that once displayed (i.e. on a Liquor Store Shelf), the bottle levels will not all line up, and that looks unprofessional and makes consumers distrust your product and brand. With a level filler, all bottles will display exactly the same.

Our Vacuum fillers are however a lot more affordable, with a similar capacity (bottles per hour) and come with a range of attachments, meaning it can be used for beer, viscous liquids, small bottles (25ml and 50ml), etc.

Both these filler types are also completely adjustable to fit any shape and volume bottle, so you will not require separate fillers for different sizes or types of bottles. One machine will do everything for you. The four head bottle filler is however not ideal for really small bottles (25ml and 50ml). We also have a dedicated filler for bottles of that size available

What should I keep in mind regarding Closures?

Your choice of closure is as important as your choice of bottle, as it adds to the perceived value of your product in how it looks and feels, while at the same time ensuring the intrinsic value of your product through the purpose it full fills in terms of sealing the product from leaks, contamination and oxidisation.

There is also a legal component to this, in that Liquor Law requires packaging to be sealed with a tamper proof seal.

The most common type of closure found on spirits bottles would be the ROPP Screw top closure – Roll-On Pilfer Proof. In the world of Craft Spirits though, product presentation is all about perceived value, and a screw top closure just does not do the products justice. Hence the most commonly used closures are cork (natural or synthetic) bar top closures – normally from Amorim Corks in Portugal. These can be quite simple, or extremely decorative and ornate, but you need to remember that a closure of this type by its very nature is not considered tamper proof and will therefore require additional sealing to make it compliant with legislation.

The most commonly acceptable ways to seal a bartop closure would be either a shrink wrap seal (heat shrink) or a wax dipped seal. Heat shrink plastic seals are probably the most common, cheapest and easiest to use, and can be either clear or coloured.

These shrink wrap capsules are applied through the even application of high temperatures. In an emergency, you could use a very powerful hair dryer to accomplish this, but normally that will lead to inconsistent sealing. For all round heat application, a heat gun is recommended.

A slightly more expensive option, but with a higher production rate, is a table top thermocapsuler – but again keep in mind whether the design will suite your bottle shape. The design pictured below is meant for round bottles (although some square bottles would work as well).

Wax Sealing is a firm favourite amongst Craft Spirit Producers, especially Whisky producers and those brands that want to lend a true old-school, handmade feel to their bottles.

Wax dipping is relatively simple – if you use the right type of sealing wax. The wax is simply melted in a Wax Melting Pot (or any pot on top of a heating element). The bottle top is dipped in the wax, removed, given a slight twist, and then dunked in cold water for the wax to set. Some producers mix in some wood glue with the wax to make it more liquid and easier to work with.

Just sealing the top of the bottle with wax is not the only option. By having a unique wax stamp made, it is possible to add a wax seal around the neck of the bottle, on the label, presentation box, etc. as well.

Keep in mind though that wax sealing can be quite expensive if you cannot source an affordable supplier of the sealing wax.

What do I need to keep in mind regarding Labelling?

Here we are not going to look so much at label design and legal requirements of the label - we will do a separate article on that - but focus more on the labelling process itself.

As discussed before – your choice of label application method is tied directly to your choice of bottle shape.

You get round bottle labellers and flat bottle labellers, but nothing in-between. As a rule, a round bottle labeller is considerably cheaper and simpler than a flat bottle labeller, due to its design and operation. It is normally also a lot faster. Although meant for straight, round bottles, the round bottle labeller can handle bottles with a slight taper, if the labels are designed and printed correctly.

At the Craft Level, we have a choice between a manual and electric round bottle labeller.

If using an non-standard bottle shape, the easiest and cheapest solution is to build a wooden mould for the bottle to ensure proper application by hand each time. Something else to consider however would be Bottle Printing or Bottle Decorations.