Barley, Malting and Malt – Part 1 of 4: Barley for Malting

adminDuring COVID-19 Lockdown, several basic Home Distilling (and Brewing) supplies – equipment and consumables - have been difficult to get hold of. Yeast, Nutrients, Enzymes and even Bubbler, SG Hydrometers and Alcoholmeters.

One of the most problematic however, was Malted Barley. Not just because stocks and supplies had run out, but because the plants producing it was shut down. Even under Level 3 Lockdown – when the plants could start operating again – it was not a situation where suddenly Malt was available again everywhere. Stocks had to be replenished, commercial Craft Brewers had to be serviced and supplied first, followed by the Craft Brewers, and only then the Home and Hobby Brewing Shops.

As a result, many Home Distillers (and Brewers) resorted to Malting their own grains and using that, but they did so armed with the most basic of information gleaned from YouTube and Online sources – most of them severely lacking.

This series of article will aim to address the shortcomings of information regarding Barley, Malt and Malting in three separate articles, focussing on Barley for Malting, the Barley Malting Process, and the Attributes of Malted Barley.

What is Malt?

Malt is Grain that has been Steeped, Germinated and Kilned according to certain procedures. Malted Grain differs from Raw Grain in several ways:

- Malt contains less moisture and therefore is more suitable for storage and grinding

- The Endosperm of Malted Grain has been modified during germination and is more pliable, in contrast to the hard Endosperm of the original Grain kernel

- Malted Grain has much higher enzymatic values than raw Grain

- Malted Grain has flavour and aroma that differs from raw Grain - due to the germination and Kilning process - and these components can be readily extracted during the starch conversion and fermentation processes

Why should a Distiller care about Barley, Malt and Malting?

Any of you who have done our W2 – Grain Based Spirits Course, or our C10 – Comprehensive Distilling Course, will know that the Grain types used, as well as the Malt and Enzyme Sources used in your Grain Fermentations will have a massive impact on the final product we produce – be that a fermented product like a Beer, or a Distilled Product, like a Moonshine, Whisk(e)y or Vodka.

Even sticking to one specific Grain type – like Barley – the quality, yield and flavor can and will vary greatly from one cultivar or varietal to another, from one season to another, or depending on how it was Malted.

Understanding these variations allows the Distiller (or Brewer) to make informed decisions and choose the Grain or Malt that would be suitable for the intended use, as well as ensure consistency in the production process and the end product quality.

Barley is the principal grain used in producing Malt, the basic raw material for brewing beer, and traditionally (in Scotland, Ireland and South Africa) the basis of Whisk(e)y. Other grains such as wheat, sorghum, maize and rye can also be Malted and will impart unique characteristics in terms of flavor, but they are not widely used as a Malted grain.

Why is Barley preferred for Brewing and Traditional Whisk(e)y Distilling?

If we want to explore the real reasons for the original use of Barley, then this will turn into a History lesson about agriculture, climatic conditions, etc.

If we want to explore the reasons for the continued use of Barley, the it will be a discussion of Tradition, Marketing and Consumer Expectations.

But there are some technical reasons – less important than the others, but still relevant.

- Barley is one of the hardiest of the cereal Grains. It can be Malted more easily than any other cereal Grain type.

- Malted Barley provides flavor, enzymes and essential nutrients for yeast metabolism, and in the case of beer, color as well.

- The Hydrolytic Enzymes developed in Malted Barley breaks down Endosperm Cell Walls, proteins and starches in both Barley and adjuncts (additional grains added into the Mash).

- The Barely Husk physically protects the kernel during Malting, and it provides the filter bed for Wort Filtration in the Mash Tun

Now it is true that many (if not all) of these attributes are shared by other grain types as well, but one thing that cannot be denied is that the Enzyme concentration in Malted Barley is much higher than in other Malted Grains, and as such, when using Malted Barley, we only need to Malt a percentage of our Grain Bill, instead of Malting the entire Grain Bill when using other Grains.

What does a Barley Kernel consist of?

A Barley Kernel consists out of four main parts:

- The Outer Layers – the husk, pericarp and testa – surrounding the endosperm and protecting the mature kernel from Microbiological spoilage

- The Endosperm – the starch bearing portion of the grain, and the aleurone, a layer two or three cells deep, which is an enzyme source

- The Embryo – the Germ Viable portion of the Grain – which is high in protein and nucleic acids. It contains the primordial root and acrospire of the young Barley plant and initiates the growth cycle when hydrated in the field or during Steeping

- The Scutellum and Epithelium, which are additional sources of Hydrolytic Enzymes

A typical composition of Barley (obviously cultivar specific) would be:

|

Component

|

Percentage of Weight

|

|

Moisture

|

10 - 14 %

|

|

Total Carbohydrates

|

65 - 80 %

|

|

Inorganic Matter

|

2 - 4 %

|

|

Fat

|

1 - 2 %

|

|

Other

|

1 - 2 %

|

How does a Distiller determine which Barley Cultivars are suitable for Malt Production?

Some varieties of Barley are bred solely for the production of feed, and some are intended for the production of Malt. Feed Barley varieties are bred for maximum agricultural yield (Agronomic reasons), with little attention given to the criteria that is critical for producing high-quality Malt.

In general, feed Cultivars or Varietals of Barley will produce Malt with higher protein levels and very poor enzyme yields and flavor characteristics.

The Varieties intended for Malt Production have been bred specifically for this purpose. They will Germinate well, withstand the Kilning process without excessive loss in enzymes, and provide a good and balanced combination of enzymes, carbohydrates and flavor will give the Distiller yield, successful conversions, and a flavorful product.

How can we improve our Malting Barley Varietals?

New Varieties of Barley for Malting purposes is continuously being developed. It is therefore important for Brewers, and to a lesser extent Distillers, to stay abreast of these developments and see what is available.

New Barley Varieties are developed and bred for characteristics such as yield, disease resistance, dormancy, modification potential (attributes that come through during Germination and Kilning), Husk Retention, Flavor and overall Malt quality.

Although it is impossible to have agreement or consensus on the make-up of the ideal Barley or Malt (due to different requirements from different producers), general guidelines for the key analytical characteristics of Barley and Malt are useful as targets for Breeders and Developers. The following Table gives some of the guidelines for Commercial Malting Barley.

|

Factors for Commercial Malt and Barley

|

Two-Row Barley

|

Six-Row Barley

|

|

Barley Factors

|

|

|

|

Plump Kernels

|

> 80%

|

> 70%

|

|

Thin Kernels

|

< 5%

|

< 5%

|

|

Germination (4 ml after 72-hour Germination)

|

> 96%

|

> 96%

|

|

Protein

|

11.5 - 13.0%

|

12.0 - 13.5%

|

|

Skinned and Broken Kernels

|

< 5%

|

< 5%

|

|

|

|

|

|

Malt Factors

|

|

|

|

Total Protein

|

11.3 - 12.8%

|

11.3 - 13.3%

|

|

Remains on 2.78 mm Perforated Screen

|

> 60%

|

> 50%

|

|

Remains on 2.38 mm Perforated Screen

|

> 90%

|

> 85%

|

|

|

|

|

|

Measures of Malt Modification

|

|

|

|

Beta-Glucan (ppm)

|

< 115

|

< 150

|

|

Fine-Coarse Difference

|

< 1.5

|

< 1.5

|

|

S/T Ration

|

40 - 46%

|

40 - 45%

|

|

Turbidity (NTU)

|

< 15

|

< 15

|

|

Viscosity (Absolute cP)

|

< 1.50

|

< 1.50

|

|

|

|

|

|

Congress Wort

|

|

|

|

Soluble Protein

|

4.9 - 5.5 %

|

5.3 - 5.9%

|

|

Extract (FG db)

|

> 81.0%

|

> 79.0%

|

|

Colour (°ASBC)

|

1.6 - 2.1

|

1.8 - 2.5

|

|

|

|

|

|

Malt Enzymes

|

|

|

|

Diastatic Power (°ASBC)

|

120 - 140

|

140 - 170

|

|

Alpha-Amylase (DU)

|

45 - 65

|

45 - 60

|

Key

NTU = Nephelometric Turbidity Units

cP = Centipoise

FG db = Fine Grind Dry Base

°ASBC = Degrees according to the American Society of Brewing Chemists)

DU = Dextrinizing Units

What is the difference between Two-Row and Six-Row Barley?

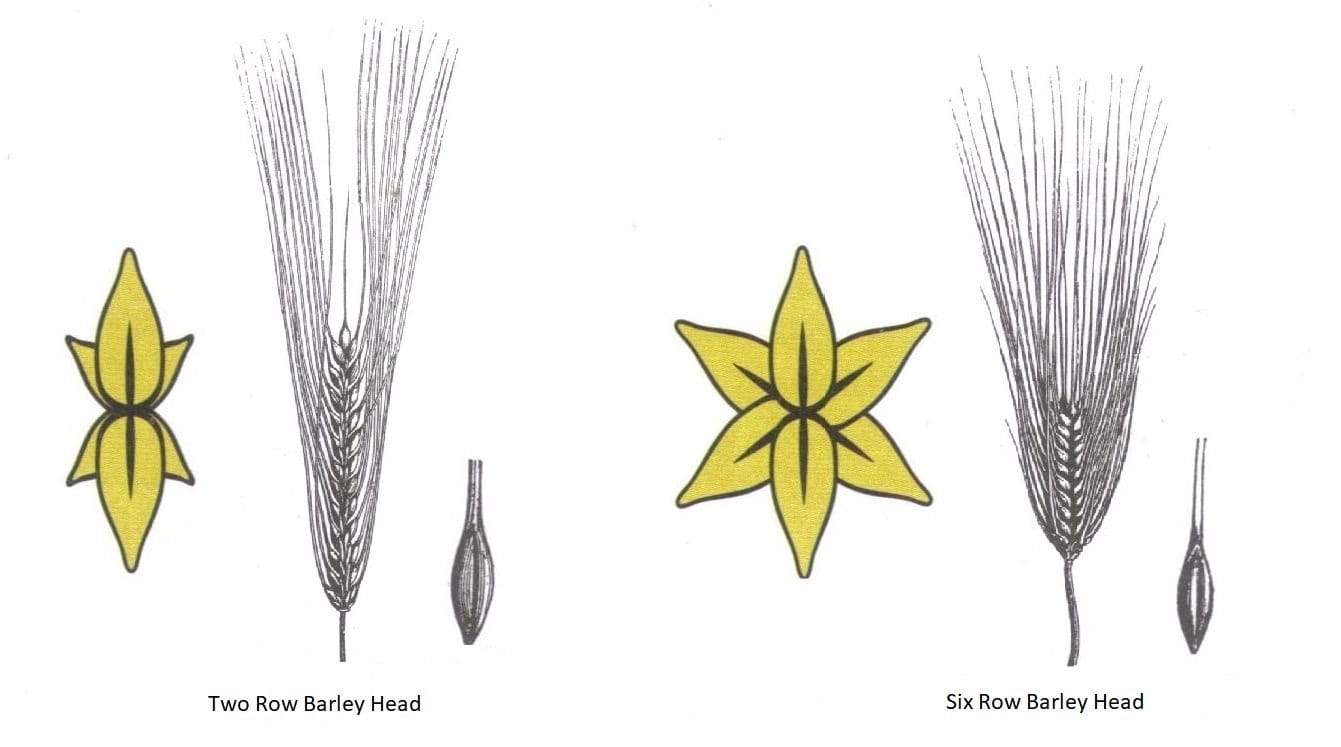

In the preceding Table, as well as in many articles regarding Barley, you will find mention of Two-Row and Six-Row Barley. This naming convention refers to the number of Kernels in the head.

- In a Six-Row variety, all six flowers surrounding the stem develop into seeds.

- In a Two-Row variety, only two of the flowers are fertile, so that only one seed forms on each side of the stem.

Because of the Kernel arrangement, Two-Row varieties generally have larger, more uniformly sized Kernels. Kernels of the Six-Row varieties are uneven in size because of the restricted space for Kernel development. The unevenness will be visually apparent, as four of the six Kernels per head will be thinner and have a twisted appearance near the distal end.

Varieties used for Malting can change rapidly, with the continual development of both Two- and Six-Row Varieties bred to offer advantages over the existing Varieties. However, even with such advances, certain varieties remain popular for long periods of time, and it is not unknown for certain Craft Distillers to stick with a certain Variety permanently in order to ensure consistency of production and flavor.

Once developed, a new Variety is normally phased in slowly in gradually increasing percentages until the older Varieties are replaced. The discontinuation of a variety is normally due to lack of disease resistance, poor yield, imperfect traits (flavor, color, enzyme concentration) or just competition from new and “better” Varieties.

Can I grow Barley for Malting?

(Adapted from an Article in Farmers Weekly – 20 January 2017)

Research programmes since 1991 have identified Barley cultivars that ensure an economical, optimal yield and grain conforming to SAB Maltings’ quality specifications. This is an overview of the research.

The article assumes an understanding of how to grow wheat, as the soil preparation is similar. Note, however, that an exceptionally fine and even seedbed is required; if you do not provide this, the crop will develop unevenly, leading to uneven ripening and quality.

Cocktail Barley and Puma Barley are currently the recommended cultivars for commercial production under irrigation.

The seed is treated with an insecticide and fungicide, the latter to prevent powdery mildew during the 10-week developmental stage of the seedlings, as well as covered and loose smut.

Choosing a Cultivar

The most important factors that determine cultivar choice are:

- Growth Period

The average number of days from emergence to maturity. To obtain this result, the cultivar must be adapted to the climatic conditions of the area. The growth period for Puma is medium fast in the right region and medium for Cocktail.

- Straw Strength

The ability of a cultivar to remain standing (no lodging) under extreme conditions is largely determined by straw length and thickness.

Lodging (bending) often results in considerable yield and grain quality loss. It is usually a problem where critical yield potential conditions have been exceeded, but poor irrigation practices and excessive nitrogen fertilization or seeding density can also play a role. Puma and Cocktail have a medium straw strength.

- Peduncle Strength

The strength of the straw between the flag leaf and the head/ear. It determines the cultivar’s susceptibility to wind damage. Puma and Cocktail have a medium peduncle strength.

- Kernel Plumpness

Determines the grade of the grain. A soil water deficit and heat stress during the grain-filling period can cause considerable losses. Puma has a medium plumpness value and Cocktail a medium low value.

Planting Practices

The planting equipment used for wheat is suitable for Barley. Do not plant Barley seed too deep, however, as this can affect seedling emergence. Optimal planting dates for the different irrigation areas in the Free State are indicated below. These may vary in certain micro-climates in the areas. Information for other provinces in South Africa was not available.

|

Region

|

June

|

July

|

||||||

|

1

|

2

|

3

|

4

|

1

|

2

|

3

|

4

|

|

|

Vaalharts / Taung

|

|

|

|

|

|

|

|

|

|

Riet River

|

|

|

|

|

|

|

|

|

|

Douglas

|

|

|

|

|

|

|

|

|

|

Luckhoff / Hope Town

|

|

|

|

|

|

|

|

|

|

Barkly-West

|

|

|

|

|

|

|

|

|

Planting density can range from 65 kg/ha to 100 kg/ha depending on the state of the seedbed, planting date, irrigation method and planter used.

The average recommended planting density is 80 kg/ha, given a 100% germination capacity and a 1 000 Kernel weight of approximately 40 g.

Aim to establish 130 to 140 plants/m² at harvesting. Between 65 kg/ha and 80 kg/ha seed ought to be sufficient under centre pivot conditions with optimal seedbed preparation. Planting density can be increased if flood irrigation is available.

The 1 000 Kernel weight and the germination capacity of the seed can vary from year to year, so adjust seeding density accordingly.

For more information about SAB Maltings requirements, phone the South African Barley Breeding Institute at 028 212 2943, or visit www.sabbi.org

You can also download additional information in the form of these two PDF Documents.

Guidelines for the Production of Small Grains in the Summer Rainfall Region

PLEASE NOTE: The information in the latter document relating to Barley only starts on page 144, and is Free State Province specific, but most of the information is generally applicable, except the ideal sowing dates.

What factors determine the quality of Barley for Malting?

First and foremost, the Maltster looks at the Variety and Purity of the Barley Received.

The next criteria are:

- Germination (generally 95% or more)

- Plumpness (normally expressed as the percentage of Kernels retained on a 2.78 mm perforation)

- Thinness (normally expressed as the percentage of Kernels retained on a 2.38 mm perforation)

- Brightness (the brighter the better)

- Staining (the less stained the better)

- Mycotoxin Content

- Heat or Frost Damage to the Embryo (assessed by Pearling – the removal of the exterior Husk)

- Protein Content

- Moisture Content

- Percentage of Skinned Kernels

- Dockage (the dust and chaff content – normally a percentage of weight)

- Bushel Weight

- Presence of Foreign Kernels

- Insect Damage

- Odor

- Presence of other Foreign Matter

The specifications for these criteria change, depending on the variety, crop year, Barley availability and concerns about a specific crop (or supplier). In addition, new analyses are continually being developed to further assist the Maltster in determining Barley Quality. Rapid Viscosity and Falling Number Analyses can be run to assess the Alpha-Amylase content, indicating whether sprout damage may have occurred. Tetrazolium staining of longitudinally split grains can be used to give a Visual Measurement of Embryo Viability – viable tissue takes on a Red Stain, whereas non-viable tissue remains colorless.

As with all Malt specifications, the Barley specifications are closely tied to the Distiller’s (or Brewer’s) needs. The single most important predictor of final Malt quality is the initial Barley quality. It is nearly impossible to make uniform, well-modified Malt from poor-quality Barley. But, having said that, should a Maltster be aware of the subtle variations in the Barley, he (or she) can compensate by making slight adjustments to the Malting process. Knowledge of Barley quality traits in each Barley delivery is just as important for the Malster as it is for the buyer of any produce or raw material.

What factors influence the quality of Barley?

Many factors influence Barley quality. The most important are the Varietal, Climatic conditions, soil conditions and storage practices.

A cool, moist growing season will favor a plumper crop with lower protein content. A hot, dry growing season will produce thinner, higher-protein Barley, which will produce Malt with lower levels of extracts.

The timing of planting can also have a significant effect.

Planting early in the growing season may allow that crop to mature prior to the hot, dry portion of the summer and may avoid late season frost damage. In any Barley growing area, the quality of the crop may vary significantly, depending on when it was planted. Irrigation is increasingly being used by Barley growers, helping to produce more uniform, higher-quality crops.

Crop rotation can also affect Barley quality. Barley grown in a field that was heavily fertilized for a different crop during the previous growing season may develop unacceptably high levels of protein. Barley grown in fields that produced corn in the previous growing season may be subject to disease caused by Micro Organisms that can overwinter on corn residue.

Harvesting and storage conditions can also materially affect Barley quality.

If there is excessive rain during the harvesting period, Barley may be stained and sprout damaged. Improper storage of grain can also reduce Barley Quality. If Barley is harvested with a moisture content greater than 14%, storage stability will be a concern. The Germinative capacity may decrease more rapidly in high-moisture Grain than in drier grain, and high-moisture Grain is more susceptible to insect infestation and heat damage from Insect activity. Proper air-drying of high-moisture Barley and effective Insect Control during storage are some of the critical success factors in maintaining Barley quality.

Why must Barley for Malting have the capacity to Germinate?

Barley must Germinate in order to produce Malt. Barley kernels that do not Germinate usually have either dead or injured embryos. Barley with at least 95% live embryos should be used for Malting. During Germination the Kernel content is modified through the action of enzymes that are released and activated in the Barley. These enzymes are also utilized later in the conversion of Starch and Proteins into more soluble fractions.

Why should the Barley for Malting have a Moisture Content of less than 14%?

Malting Barley must be able to withstand storage for many months. Barley with a high moisture content is apt to heat in storage and lose Germinative capacity as a result. For this reason, it is desirable that Barley intended for Malting purposes have a moisture content of not more than 14%. Barley with a higher moisture content must be either air-dried before storage, Malted quickly, or rejected out of hand.

What is the effect of Kernel size in Malting?

To the Maltster, Kernel size is an important factor to consider in determining processing parameters for the Malting Process, primarily because the water uptake rate of Barley Kernels in inversely proportional to their size, i.e. the smaller the Kernel, the faster it absorbs water during Steeping, while the larger the Kernel, the slower it absorbs water during Steeping.

For the Distiller, size impacts on other factors. Larger Kernel size is generally associated with more extracts (for Kernels of the same Variety), and Kernels of uniform size can be milled more efficiently than Kernels of variable size – the latter directly impacts on the mill settings in the Distillery.

Sieves are normally used to sort Kernels by size. Distillique’s Specifications List for Sieves should clear up some of the confusion in terms of the different metrics used to describe Sieves.

What color and odor should Malting Barley have?

Mature Barley should be uniformly light to dark golden yellow. However, color is not the most important factor in determining Barley quality. It is merely another criterion for determining suitability for Malting. Malting Barely should have the odor of clean grain, and be free of objectionable odors, such as those produced by heated, musty or moldy grain.

Is stained our moldy Barley unsuitable for Malting?

Stained of Moldy Barely may not store or Germinate properly, and these unwanted characteristics may carry over in the taste and smell of the final product. The key factor responsible for staining is weather conditions during the growing season. Moist, wet growing conditions, while favorable for yield and Kernel plumpness, promote staining and the growth of mold in Barley. The incidence of staining and mold may be different in each crop year and agricultural area. Stained and moldy Barley must be carefully examined, but if its Mycotoxin content, moisture and germination potential are acceptable it can be used to produce good Malt.

What is undesirable about Barley not fully ripened in the field?

Immature Barely Kernels are greenish white and are usually long and thin. They differ greatly in composition from fully matured, plump Kernels and may cause difficulties in Malting.

How does Barley protein content influence Malt quality?

The Protein content of Malting Barley is directly related to the total protein, soluble protein and free amino nitrogen content of the Malt, and inversely related to the extract content of the Malt. In general, the higher the Protein Level of a Variety, the higher the overall enzyme package it will produce during Malting. This can result in more highly modified Malt. The friability of Malt is also inversely related to the protein content of the Barley.

The Barley protein level is factored into the Maltster’s processing decisions. Water uptake during Steeping occurs more slowly in high-protein Barley. The Germination and Kilning parameters may be adjusted to compensate for the higher enzyme levels, and higher color potential associated with high-protein Barley. The latter impacts solely on Malted Barley for Brewing and not for Distilling.

High-protein Barley does not produce bad Malt – it merely produces Malt with an analysis and flavor signature different from that of lower-protein Malt. The Maltster’s Malting Practices can compensate for these differences but cannot eliminate them.

What is the importance of the Barley Husk?

The Barley Husk serves to protect the Kernel during Malting. The Husk is also essential in the formation of a Filter Bed in the Mash Tun during Lautering. Husks contribute very little to the overall Malt Analysis, but they do affect the flavor profile of the fermentation, and in the case of Beer, it can also affect Beer stability.

How soon should Barley be Malted, and how is it stored?

Barley harvesting occurs over a period of one to two months. This supply of Barley must now last for at least 12 months. Freshly harvested Barley will usually not Germinate at its optimum, so it is common to store Barley for 1 to 3 months prior to full-scale Malting. During this initial post-harvest aging period, Maltsters will conduct Laboratory, Pilot-scale and limited Full-scale trails to generate as much information as possible on what to expect from the new crop.

Storage bins or Silos are generally constructed of either concrete or steel. Steel bins have a bigger footprint and usually more conveyance than the more compact slip-formed concrete silos. Steel bins are also usually much less expensive to construct that concrete silos. Both storage systems work well for both Malt and Barley. The bins or silos are filled from the top by way of spouts. Grain is conveyed mechanically to a spout and drops into the bin under the force of gravity. Most bins have conical bottoms to facilitate easy cleaning. The bin or silo discharges from this conical bottom into a conveyor that leads to an elevator leg. This system can be used to turn or transfer grain for aeration and conditioning. Screw conveyors and drag conveyors are commonly used to transfer Barely. Belts and drag conveyors are preferred for Malt, because of its high friability.

Why should each batch of Malting Barley be from the same Variety?

Varieties differ in both Physical and Chemical composition, as well as in Biological activity. One of the most important tools of the Maltster is detailed knowledge and understanding of each batch of Barley that he or she needs to Malt. This knowledge allows the Maltster to adjust the Malting Process Parameters to ensure that each step in the Process will help to create the best possible Malt.

This brings us to the end of the first of our three articles on Barley, Malting and Malt. The journey continues in the next articles - the Barley Malting Process, and the Attributes of Malted Barley.

1 comment

very detailed and technical artile.

would like all three of them.